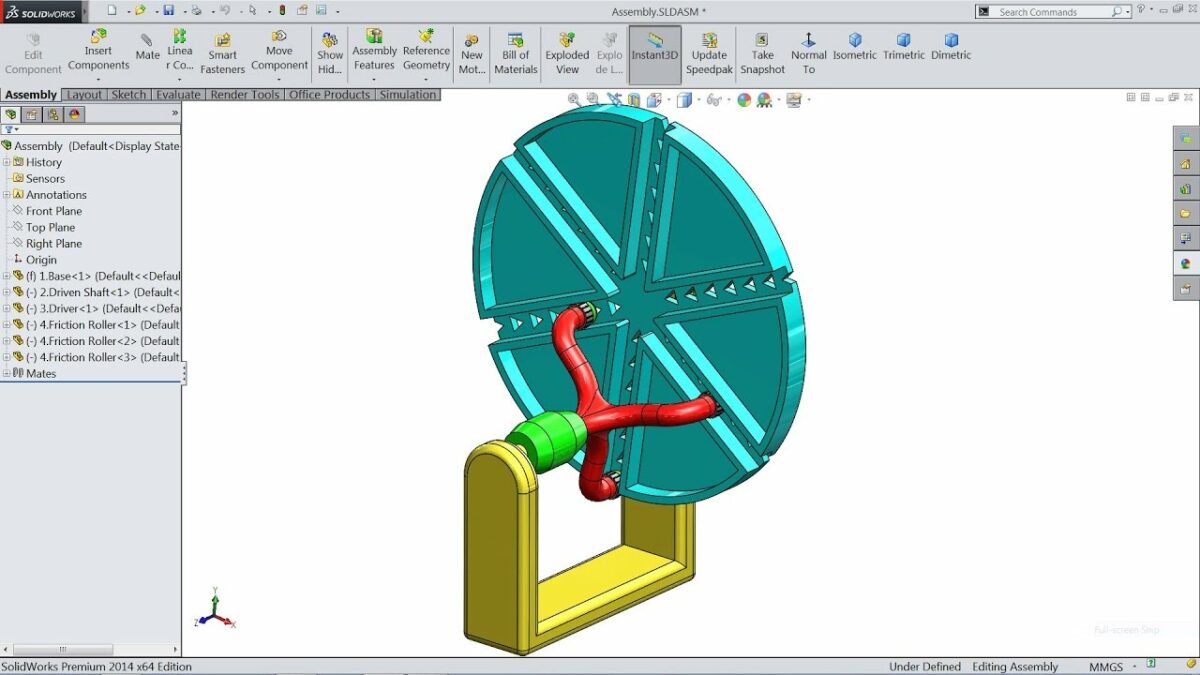

Introduction: SolidWorks, a leading computer-aided design (CAD) software, provides engineers and designers with powerful tools to simulate and analyze motion in mechanical assemblies and designs. Motion studies in SolidWorks enable users to visualize, analyze, and optimize the movement of components, mechanisms, and systems within their designs. In this comprehensive guide, we’ll explore the intricacies of creating motion studies in SolidWorks, covering fundamental concepts, essential techniques, and advanced strategies to help you master this vital aspect of CAD simulation and analysis.

Understanding Motion Studies in SolidWorks: Motion studies in SolidWorks simulate the dynamic behavior of mechanical assemblies and components by defining motion trajectories, constraints, and interactions. These studies enable users to analyze various aspects of motion, including displacement, velocity, acceleration, forces, and collisions, to validate design performance and functionality. Before delving into the specifics of creating motion studies, it’s crucial to grasp some foundational concepts:

- Types of Motion Studies:

- SolidWorks supports various types of motion studies, including basic motion, assembly motion, motion analysis, and kinematic motion. Each type of motion study offers specific capabilities and functionalities for simulating different aspects of mechanical motion and behavior.

- Motion Simulation Tools:

- SolidWorks provides a comprehensive set of motion simulation tools, including mates, motors, springs, dampers, contacts, and sensors, to define and control motion behavior accurately. These tools allow users to create realistic motion simulations and analyze design performance effectively.

- Motion Analysis Parameters:

- Motion studies in SolidWorks involve defining parameters such as time, displacement, velocity, acceleration, and forces to simulate and analyze mechanical motion accurately. Users can specify motion trajectories, constraints, and interactions to replicate real-world behavior and conditions.

Creating Motion Studies in SolidWorks: SolidWorks offers intuitive tools for creating motion studies, allowing users to simulate and analyze mechanical motion with precision and accuracy. Let’s explore the essential steps for creating motion studies:

- Activate Motion Study Environment:

- Begin by activating the Motion Study environment in the SolidWorks assembly or part file. You can access the Motion Study tab from the CommandManager or the MotionManager tree to start creating a new motion study.

- Define Motion Components:

- Define the components and mechanisms involved in the motion study by adding mates, constraints, and motion controllers. Use SolidWorks assembly tools to assemble components and define their relationships, connections, and degrees of freedom accurately.

- Add Motion Controllers:

- Add motion controllers such as motors, springs, dampers, and actuators to define and control the motion behavior of components within the assembly. Specify motion parameters, trajectories, and constraints to simulate realistic motion scenarios and conditions.

- Set Simulation Parameters:

- Set simulation parameters such as time duration, time step, and calculation options to define the scope and accuracy of the motion study. SolidWorks provides options for configuring simulation settings to achieve the desired level of detail and fidelity in the motion analysis.

- Run and Analyze Motion Simulation:

- Run the motion simulation to visualize and analyze the behavior of components and mechanisms within the assembly. SolidWorks provides real-time animation and visualization tools to observe motion trajectories, displacements, velocities, accelerations, and forces during the simulation.

- Evaluate Results and Performance:

- Evaluate the results and performance of the motion simulation by analyzing key metrics such as displacement, velocity, acceleration, forces, and collisions. SolidWorks offers tools for plotting motion data, generating reports, and identifying areas for optimization and improvement.

Advanced Motion Study Techniques: In addition to basic motion simulation tools, SolidWorks offers advanced techniques to enhance motion study creation workflows and achieve precise analysis objectives:

- Parametric Motion:

- Utilize parametric motion techniques to define motion trajectories, constraints, and interactions based on mathematical equations, functions, or user-defined parameters. Parametric motion enables users to simulate complex motion scenarios and dynamic behavior accurately.

- Optimization and Sensitivity Analysis:

- Perform optimization and sensitivity analysis on motion studies to identify optimal design configurations and parameter values. SolidWorks provides tools for varying design parameters, constraints, and objectives to optimize design performance and achieve desired goals.

- Contact and Collision Detection:

- Enable contact and collision detection features in motion studies to simulate interactions between components accurately. SolidWorks detects and visualizes collisions, interferences, and clearance violations during the simulation, allowing users to identify and resolve potential issues early in the design process.

Best Practices for Motion Studies: To maximize accuracy, efficiency, and effectiveness when creating motion studies in SolidWorks, it’s essential to adhere to best practices:

- Define Clear Objectives and Constraints:

- Define clear objectives and constraints for the motion study, including motion requirements, boundary conditions, and performance criteria. Establishing clear goals and constraints helps focus the simulation efforts and ensures relevance to design objectives.

- Start Simple and Iterative:

- Start with simple motion scenarios and gradually increase complexity as needed. Iteratively refine the motion study by adding components, constraints, and controllers, and evaluating results at each iteration to ensure accuracy and convergence.

- Validate Against Real-World Data:

- Validate motion study results against real-world data, measurements, or physical experiments to ensure accuracy and reliability. Compare simulation results with empirical observations to identify discrepancies and validate the simulation model and assumptions.

- Document and Communicate Results:

- Document motion study setup, parameters, results, and conclusions systematically to facilitate review, validation, and communication with stakeholders. Use visualization tools, animations, and reports to convey findings effectively and support decision-making processes.

Conclusion: Motion studies in SolidWorks provide engineers and designers with powerful tools to simulate, analyze, and optimize mechanical motion within assemblies and designs. By mastering the tools and techniques for creating motion studies, you can enhance your design process, validate design performance, and optimize product functionality effectively. Whether you’re a novice or an experienced SolidWorks user, understanding the principles of motion simulation and adhering to best practices will elevate your CAD skills and enable you to create innovative, reliable, and high-performance mechanical designs efficiently.