In the realm of CNC machining, efficiency and quality are paramount. Optimizing cutting strategies in PowerMill Ultimate empowers you to achieve both. These strategies define how the cutting tool interacts with the workpiece, influencing factors like material removal rate, surface finish, machining time, and ultimately, the cost-effectiveness of the finished part. This comprehensive guide delves deeper into optimizing cutting strategies within PowerMill Ultimate, equipping you with advanced techniques to transform your machining processes from good to great.

Beyond the Basics: Delving into Advanced Optimization Techniques

Having grasped the fundamental principles (covered in our previous installment), we now explore advanced methods for optimizing cutting strategies in PowerMill Ultimate:

Machine Learning and Adaptive Machining: PowerMill Ultimate integrates with advanced functionalities that leverage machine learning algorithms. These algorithms can analyze toolpath strategies, sensor data from the machining process (cutting forces, vibrations), and historical machining data to dynamically adjust cutting parameters (spindle speed, feed rate) in real-time. This “adaptive machining” approach optimizes machining conditions throughout the process, maximizing material removal rates, minimizing tool wear, and ensuring consistent surface finish.

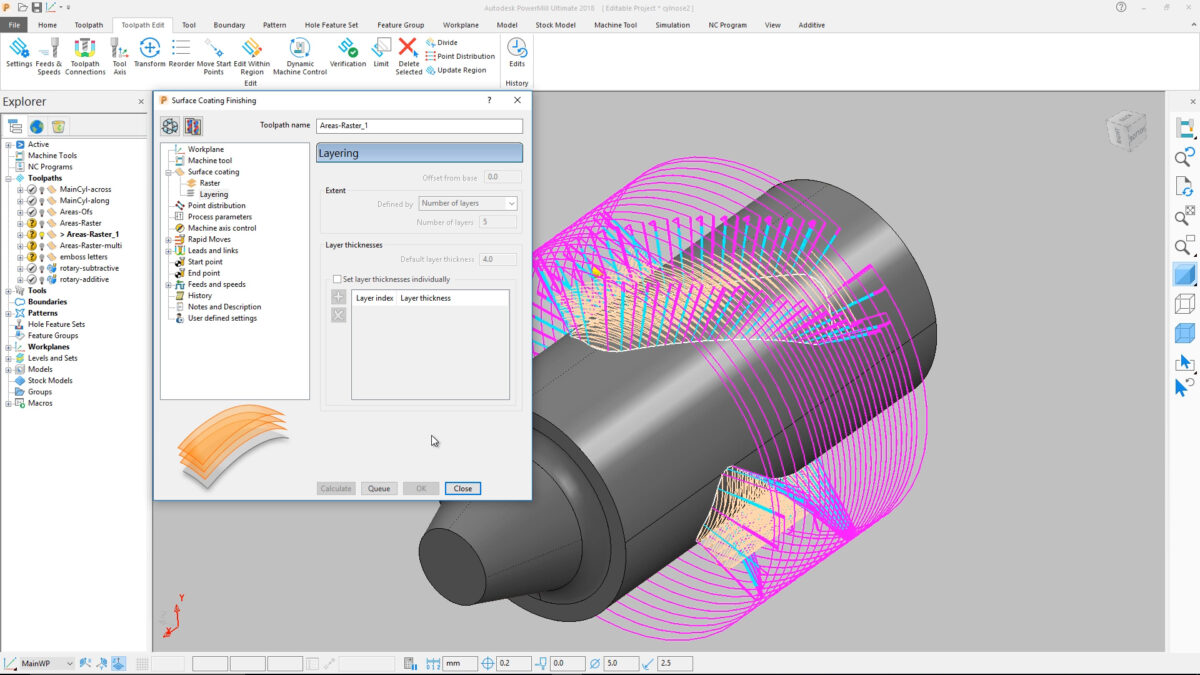

Multi-Area Machining: This functionality allows you to define separate machining strategies for different areas of the workpiece within a single toolpath. For instance, you might employ a roughing strategy for removing bulk material in specific regions and a finishing strategy for achieving a smooth surface finish on other areas. This targeted approach optimizes machining time and toolpath efficiency.

Rest Machining with Optimized Strategies: Rest machining involves efficiently machining features within previously machined areas of the leftover material (stock). PowerMill allows you to define rest boundaries and generate optimized toolpaths specifically designed for rest machining scenarios. These strategies often utilize techniques like Flowline Milling for efficient chip evacuation within tight clearance areas.

Toolpath Linking and Chaining: PowerMill offers functionalities to link and chain individual toolpaths together. This optimizes tool travel time by minimizing tool retracts and non-cutting movements between features. By strategically linking toolpaths, you can significantly reduce machining time and improve overall process efficiency.

Multi-Axis Toolpath Optimization: For complex geometries requiring 5-axis machining, PowerMill’s optimization functionalities become even more critical. The software analyzes the 5-axis toolpath motions and suggests adjustments to minimize tool axis changes and optimize tool engagement throughout the machining process. This reduces machining time and tool wear while maintaining the desired surface finish and dimensional accuracy.

Considering Special Machining Applications: Tailoring Strategies

PowerMill Ultimate caters to various machining applications, each with its own optimization considerations:

High-Speed Machining (HSM): When employing HSM techniques with smaller diameter tools and significantly higher spindle speeds, reducing cutting forces becomes paramount. Optimizing cutting strategies in HSM often involves lowering chip loads and employing smaller step-over values to minimize tool deflection and ensure smooth surface finishes.

Mold Machining: Mold machining demands exceptional surface quality and intricate detail reproduction. Strategies like ball nose finishing and constant scallop finishing become crucial for achieving these requirements. Additionally, careful tool selection and meticulous toolpath optimization are essential for minimizing tool marks and ensuring part fidelity.

Advanced Material Machining: Certain materials, like titanium or Inconel, present unique challenges. Optimizing cutting strategies for these materials often involves employing specific tool geometries and coatings, utilizing lower cutting speeds and higher feed rates to manage chip formation, and employing aggressive cooling strategies to prevent tool wear and thermal issues.

By understanding the unique requirements of each machining application, you can tailor your cutting strategies in PowerMill Ultimate to achieve optimal results.

The Future of Cutting Strategy Optimization: Embracing Emerging Technologies

The future of cutting strategy optimization in PowerMill Ultimate is brimming with exciting possibilities:

Cloud-Based Optimization: Cloud computing offers the potential for real-time access to vast databases of machining data. PowerMill might integrate with cloud-based platforms, allowing users to leverage this data to optimize cutting strategies based on similar machining scenarios performed worldwide.

Advanced Process Simulation: Advancements in simulation technology could lead to even more realistic virtual representations of the machining process within PowerMill. This would allow for more precise optimization of cutting strategies, considering factors like machine dynamics and tool deflection in greater detail.

Integration with Additive Manufacturing: The growing integration of additive manufacturing with CNC machining opens new doors for optimization. For instance, strategically placed support structures, created through additive manufacturing, could enable more aggressive cutting strategies during subtractive machining with PowerMill.

By embracing these emerging technologies, PowerMill Ultimate is poised to further empower users to optimize cutting strategies and achieve unparalleled efficiency and quality in their CNC machining endeavors.